Solving Trouble and Dissatisfaction of Transfer Pumps in a Single Stroke

With rotary volumetric pumps and other conventional pumps, there has always been the danger of liquid leakage and intrusion of foreign matter. What’s more, disassembly and maintenance has always been a major source of troublesome tasks.

The TACMINA APL Series of universal pumps provides a total solution for all of your pump-related troubles.

As well as demonstrating excellent discharge accuracy and resistance to wear, the APL Series drastically reduces labor during maintenance and helps improve the reliability of processes.

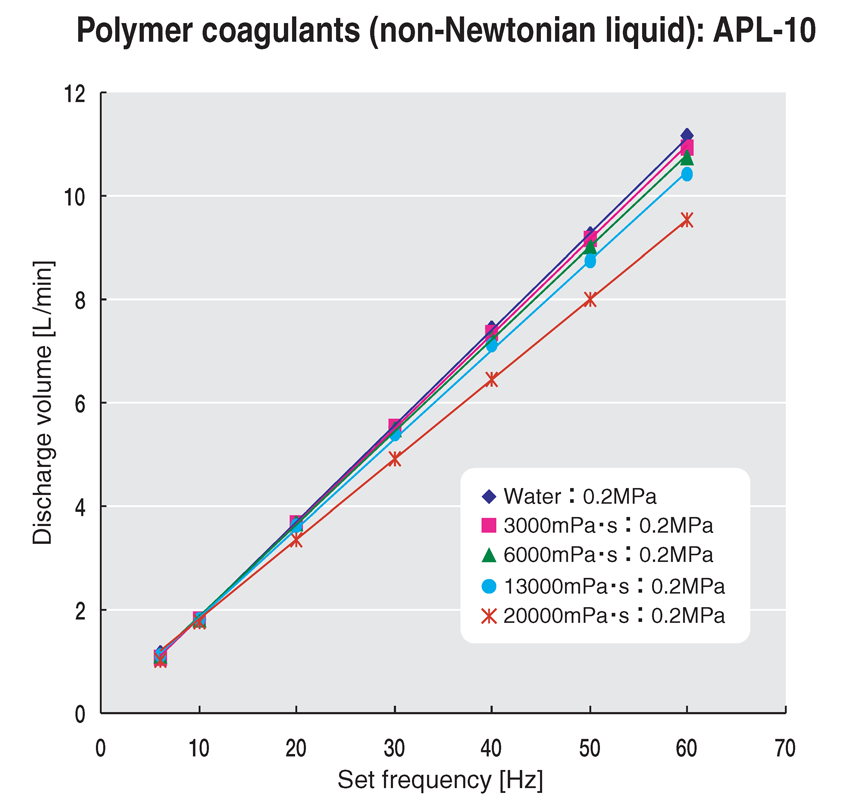

HIGH-VISCOSITY LIQUIDS

Up till now, the transfer of high-viscosity liquids has been generally regarded as difficult. However, thanks to a special pump head structure designed to minimize resistance and contamination, Smoothflow pump can transfer high-viscosity liquids such as polymer coagulants without any problem.Examples ・ Resin raw materials ・ Adhesives ・ Grease/oil ・ Liquid polymer coagulants … etc.

Performance

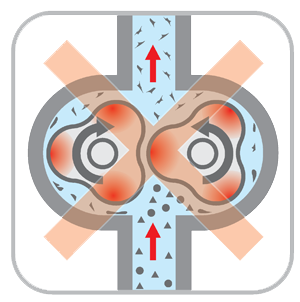

No leakage

The Smoothflow pump differs from rotary pumps in that it is a completely sealed structure free of mechanical seals. This means that there is no risk of transferred liquids leaking to the outside.

No Entry of Foreign Matter

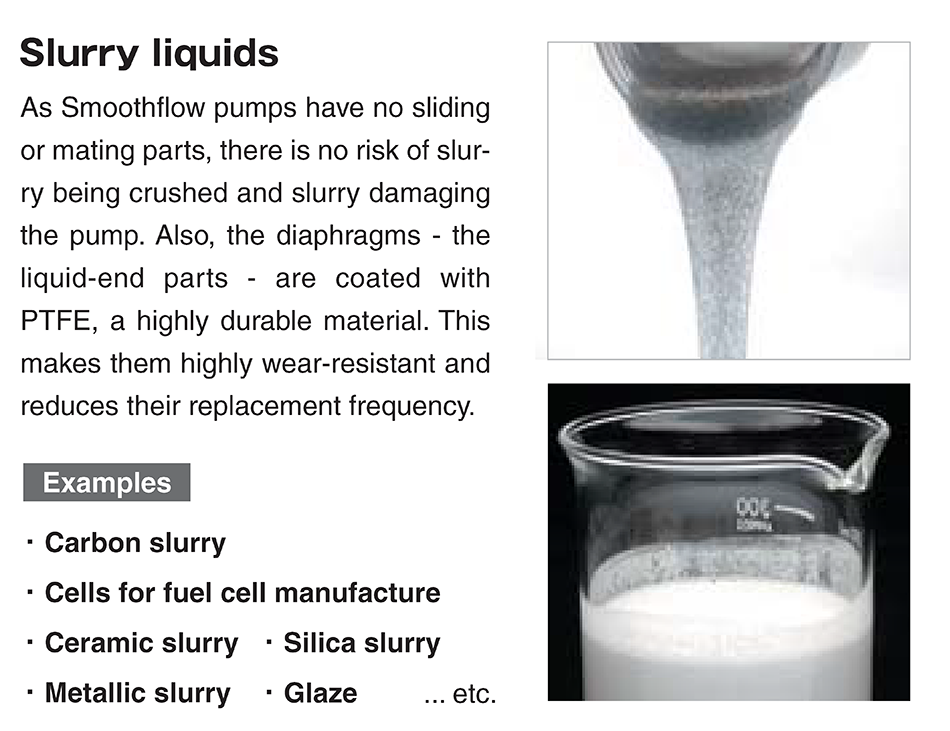

Abrasion that creates powder does not arise as Smoothflow pump has no sliding parts at liquid-end sections. This means that you need not worry about powder or foreign matter entering the pump.

No Damage to Liquid

Unlike other types of pumps, Smoothflow pump does not stir or apply excessive pressure locally on liquids. This makes it ideal for transferring delicate liquids whose properties are easily changed by shear, abrasion, pressure, and temperature change.

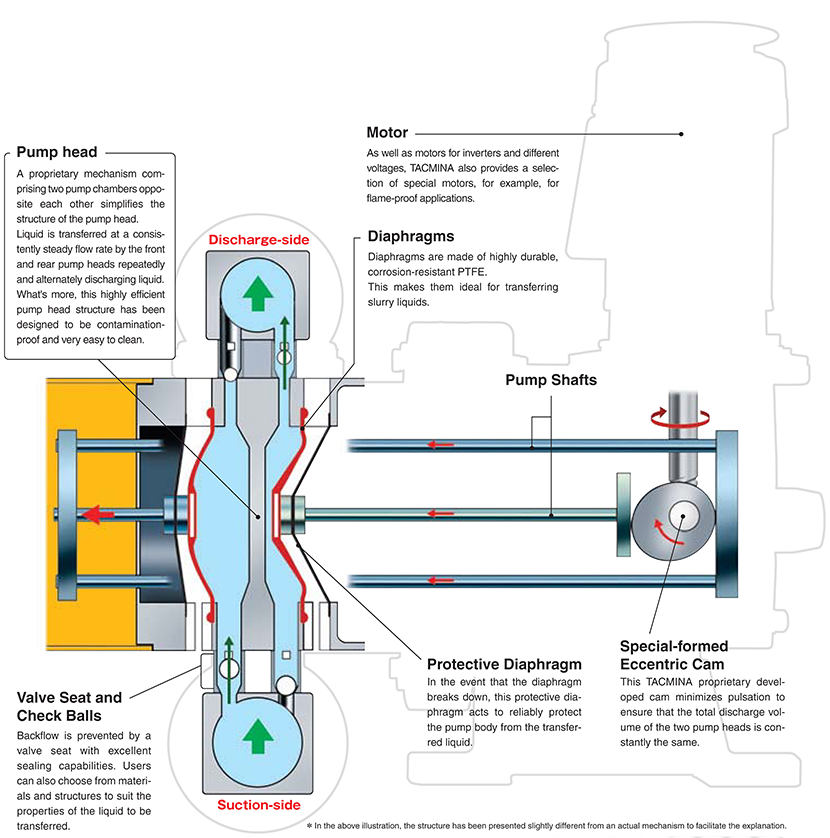

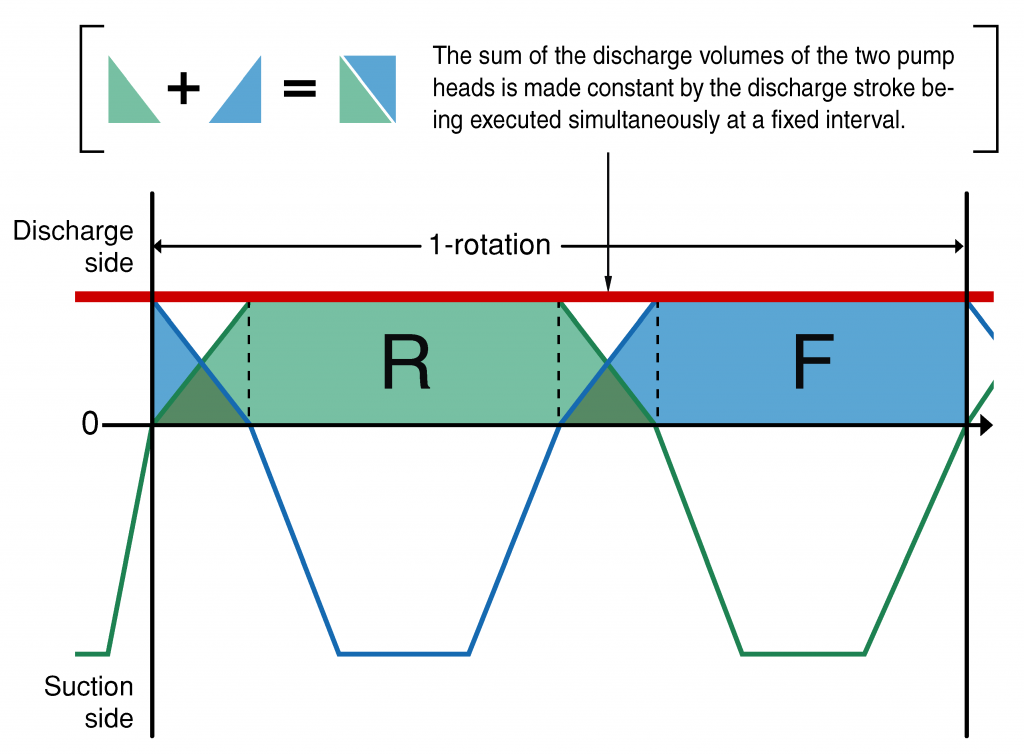

No Pulsation

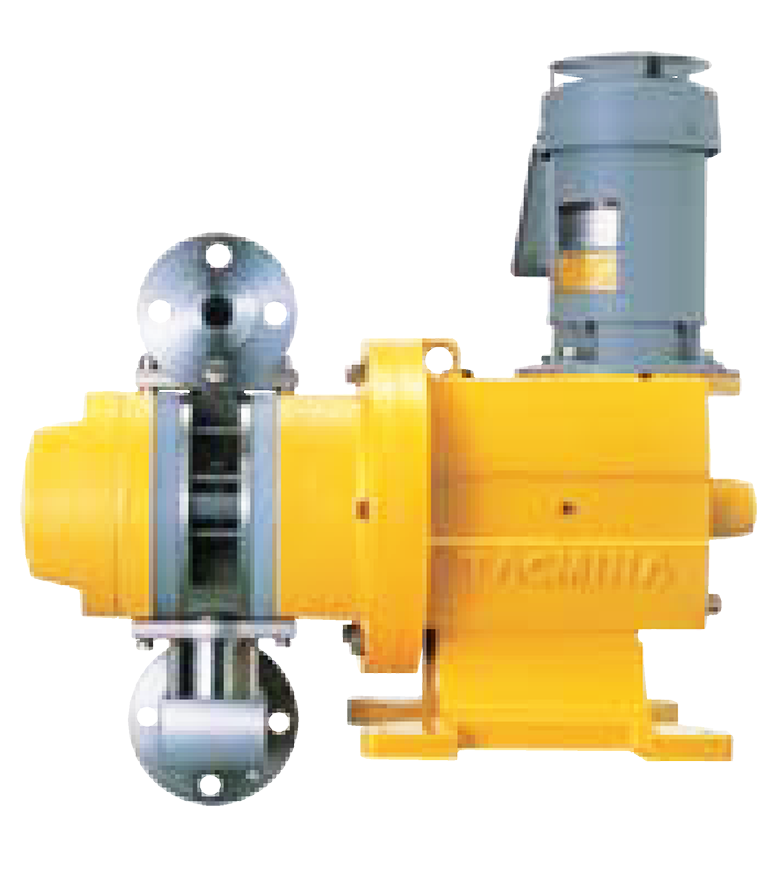

The APL Series uses a 1-cam, 1-head, 2-diaphragm mechanism, unlike anything else on the market, to suppress pulsation that is a characteristic of diaphragms. Continuous pulseless flow results in excellent metering characteristics and response to flow rate control. What’s more, as chemicals can be transferred smoothly, there is little piping resistance. In this respect, the pump excels in the transfer of chemicals over long distances.

Excellent Linearity

Backflow of transferred liquid is reliably suppressed by valve seats with excellent sealing performance. This eliminates big drops in flow rate even if the pressure in the discharge-side piping changes.

(Little Flow Rate Fluctuation)

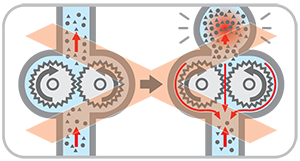

Durabilty and Long-life

High Abrasion Resistance

Diaphragms are coated with highly durable PTFE, and need to be replaced once every year or after 4000 hours of operation. This considerably reduces the replacement frequency of parts, that previously had to be frequently replaced, and helps lower running costs.

Dry-running Possible

Smoothflow pumps have no sliding parts which used to be required in rotary pumps due to their structure. This means that there is no risk of seals wearing or seizing during idling.

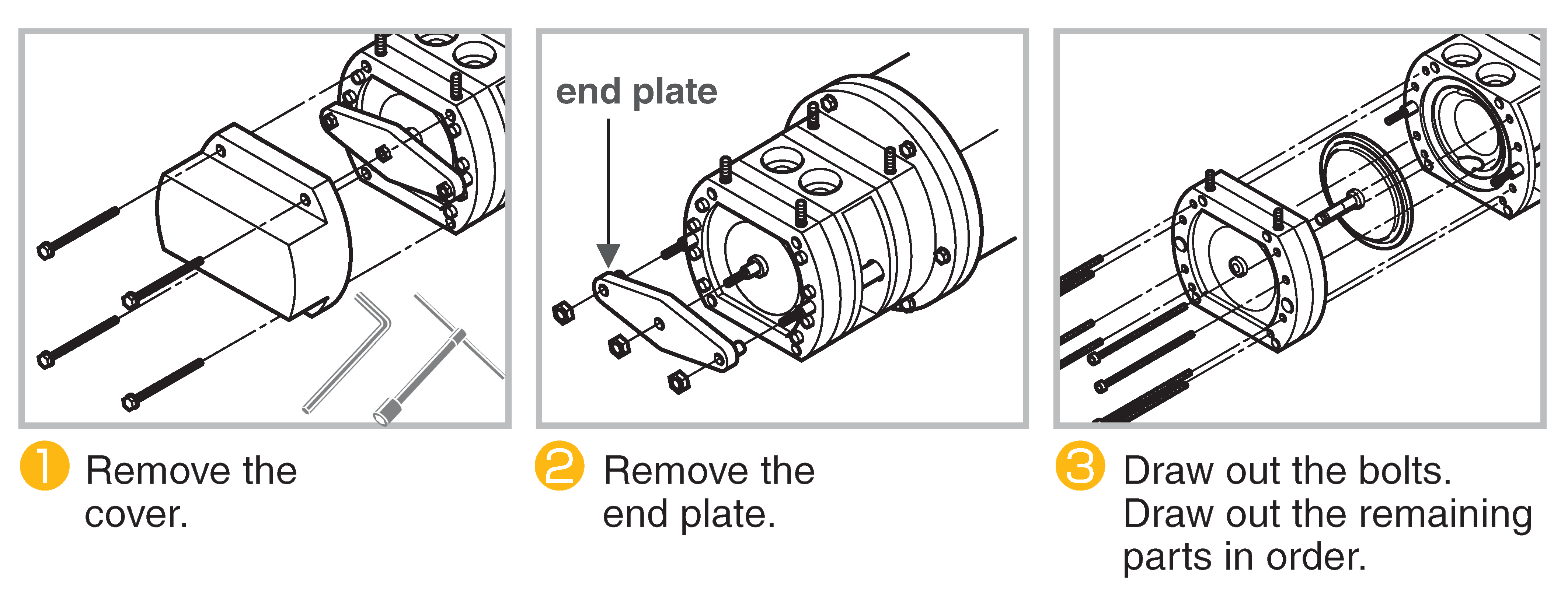

Maintainability and Installation

Simple Disassembly/Assembly

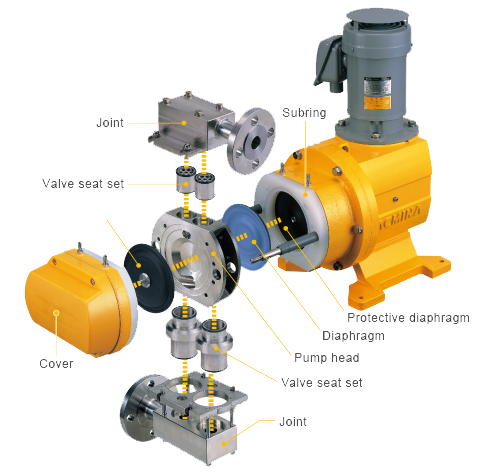

The APL Series is extremely easy to maintain. All you need is two different kinds of wrench, anybody can easily disassemble and assemble liquid-end sections.

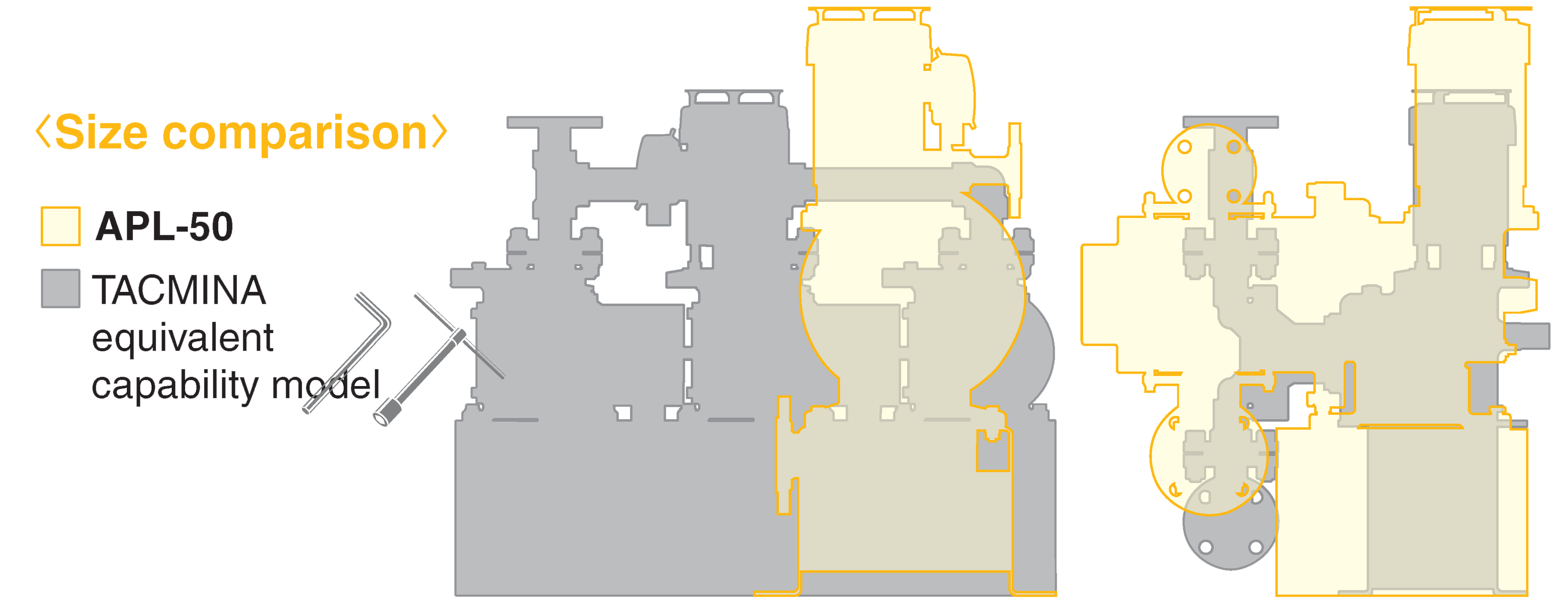

Space-saving

Integrating the pump heads into a single head greatly saves installation space. This, in turn, solves a variety of problems – selection of installation site and gaining access space during piping and maintenance.

Few Parts, Low-cost

The consumables required on the APL Series are only diaphragms, valve seat sets and O-rings that enable low cost in- vestment. Parts can be easily replaced, which means drastic savings in maintenance costs and labor.

Easy Piping

The joints on both the suction and discharge sides can be changed to face the opposite direction. This allows you to install the pump to conform to the piping conditions, for example, when it is integrated in a system.

Applications

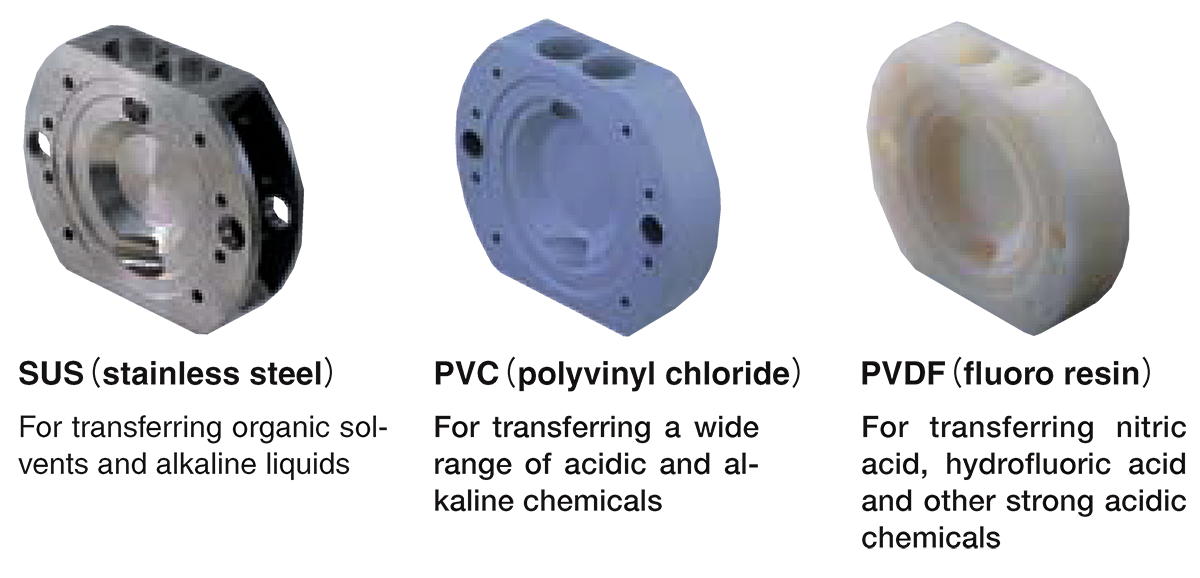

Compatible with a Variety of Liquids

Pump heads can be provided in a variety of materials such as PVDF in addition to stainless steel and PVC to suit customer specifications. This allows acidic, alkaline and various other chemicals to be transferred.

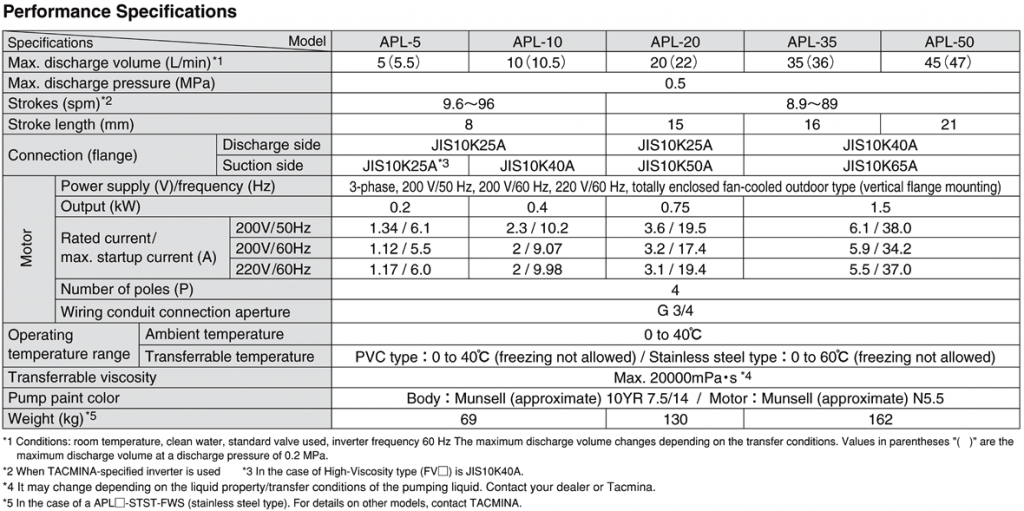

Transfer both Small and Large Amounts

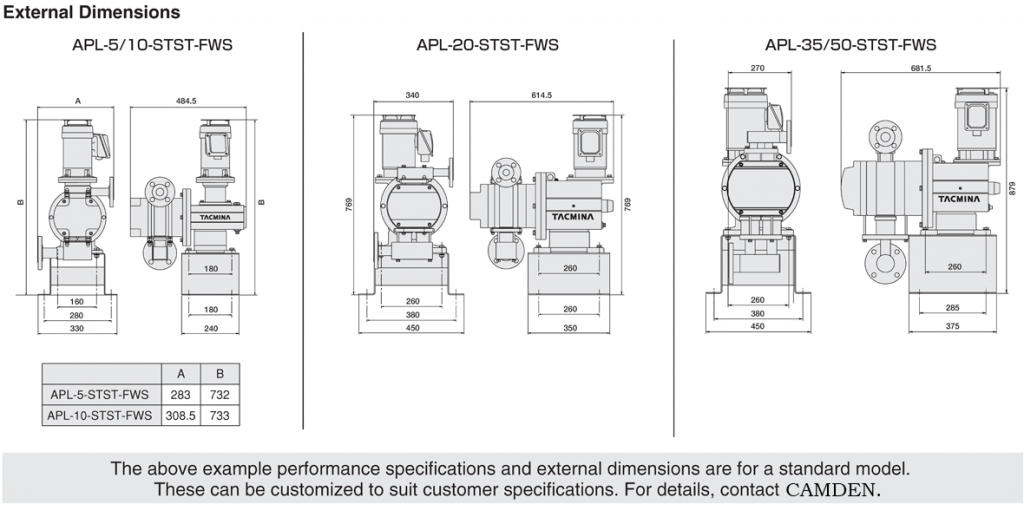

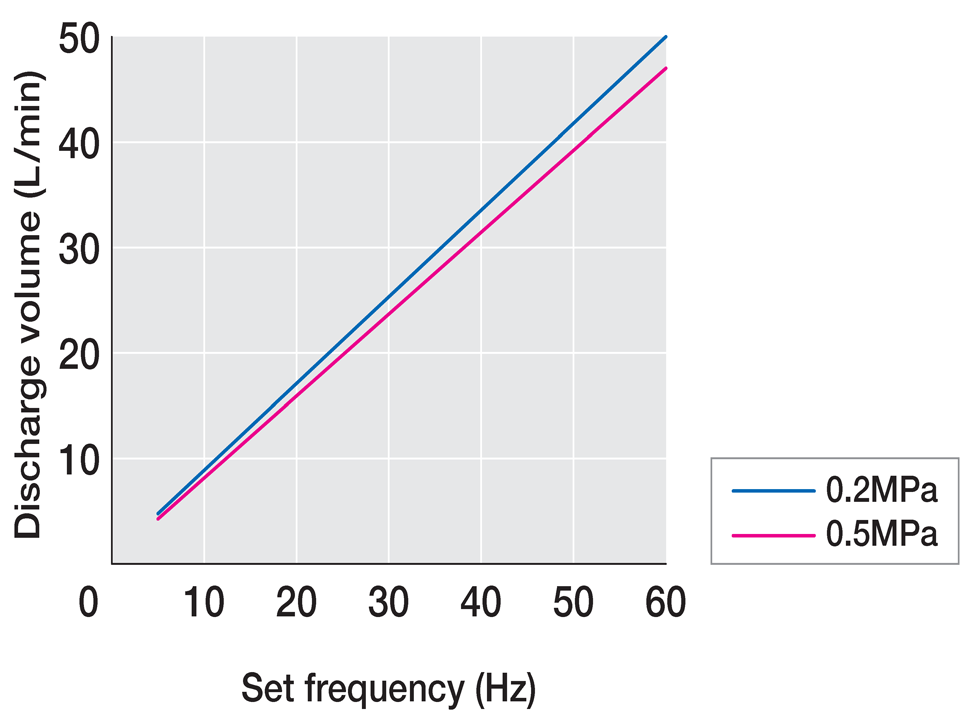

A line-up of five models – compact thru to large-size model – is available to support a maximum discharge volume range of 5 L/min extending through to 47 L/min.

Choose the pump to suit your capacity and application.

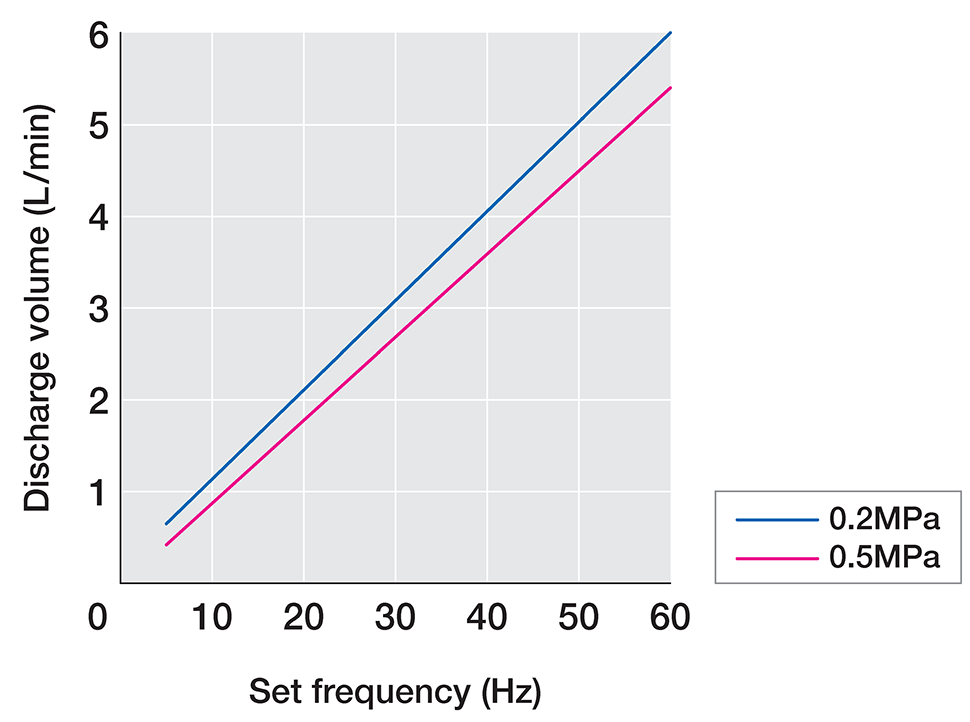

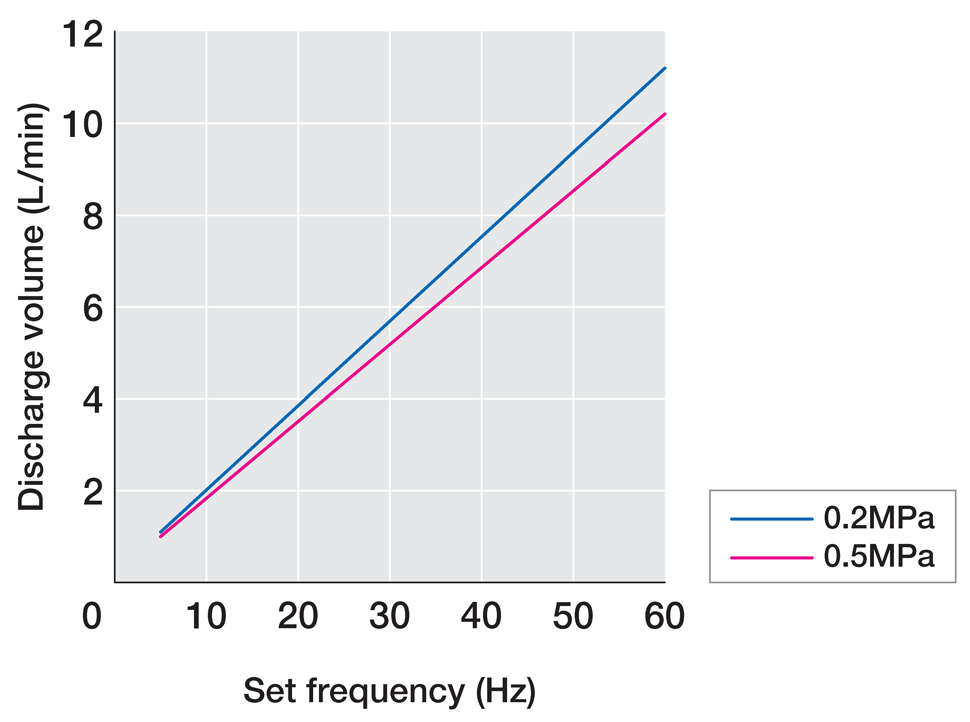

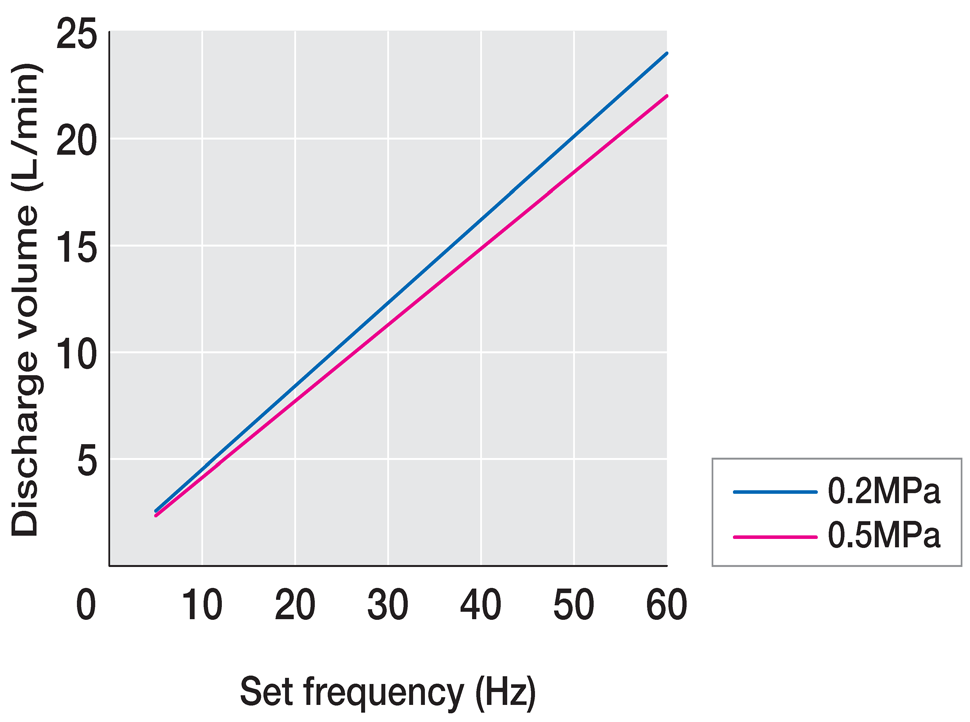

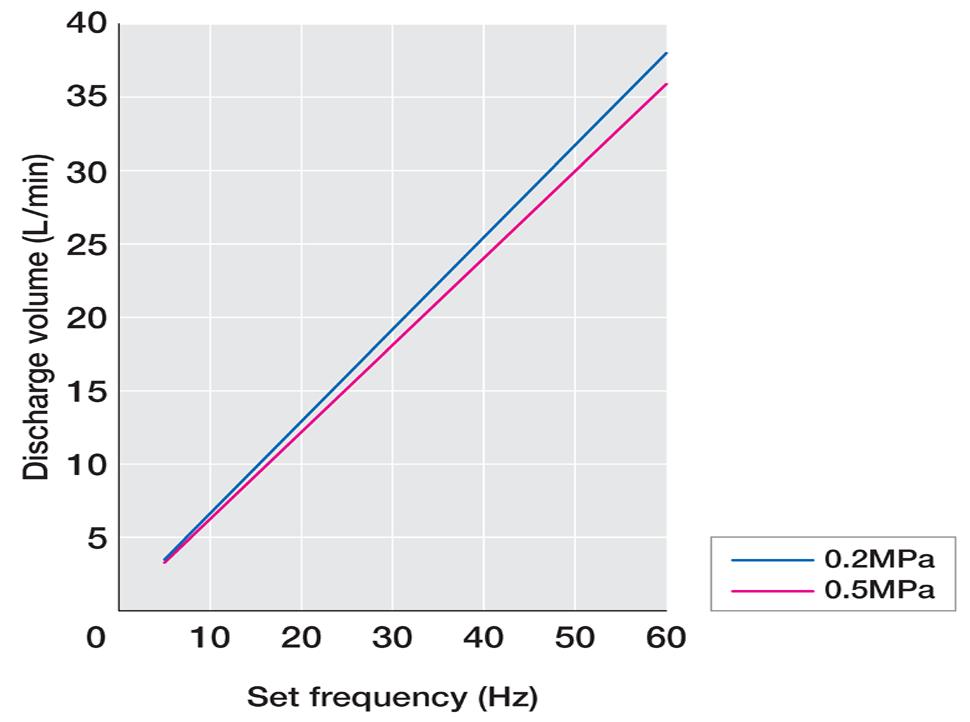

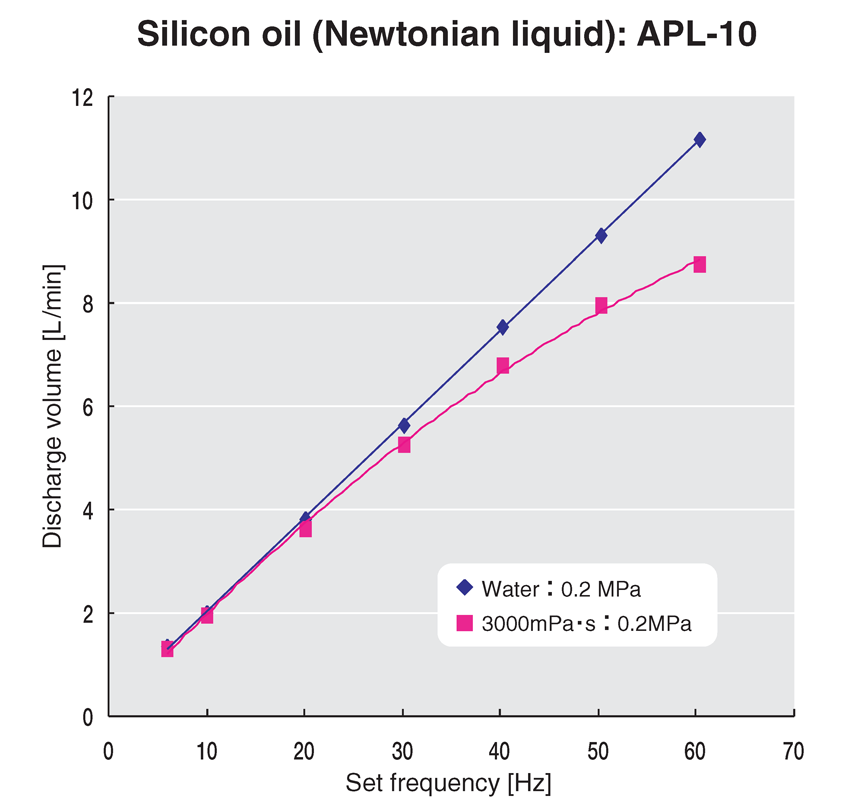

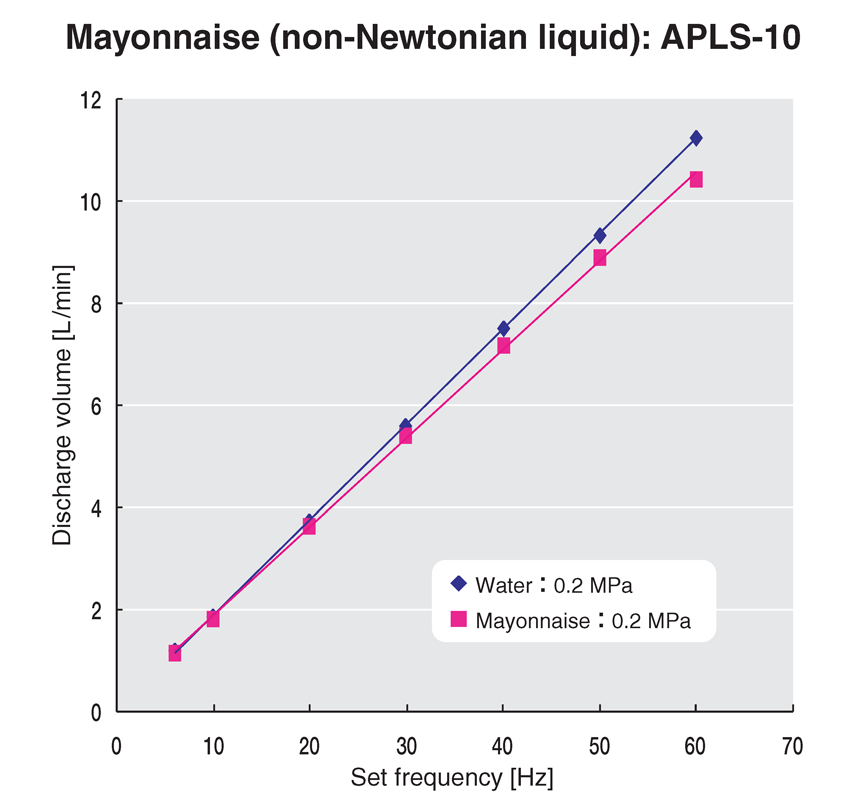

Performance Curves of APL Models

The example performance curves were obtained by measuring on test equipment at TACMINA under the following conditions.

Performance may differ slightly depending on the properties of the transferred liquid, operating conditions and product differences.

Measure the discharge volume under actual operating conditions, and set the frequency according to the performance curve that is obtained.

- Conditions : Clean water, room temperature

Relief Valve

- This relief valve automatically releases excess pressure that builds up in the discharge-side piping of the pump to prevent unexpected accidents.

* Install the relief valve near the pump on the discharge- side piping.

* Note that the relief valve will no longer be able to operate correctly if dirt builds up on the seal section.

Back Pressure Valve

- This valve prevents overfeeding*1 and siphoning*2 phenomena.

- Provide the back pressure valve near the injection point on the discharge-side piping.

*1 Phenomenon where the momentum (inertia) of the push process in a flow having pulsation causes discharge to continue even in the stroke in which the pump is not discharging

*2 Phenomenon where chemicals are sucked out naturally and continue to flow even with pump operation stopped as the tip of the pump’s discharge-piping is located lower than the level of the liquid in the suction-side tank

* Note that the back pressure valve will no longer be able to operate correctly if dirt builds up inside the valve.

Pressure Gage

- Use this device to adjust the back pressure valve and relief valve.

Valves

- When expensive liquids or dangerous chemicals are to be transferred, provide valves at appropriate locations to prevent chemical leakage to the outside during maintenance, for example.

Y-shaped Strainer

-

Provide this strainer on the suction side to prevent the entry of dirt and other foreign matter.

Flexible Joint

- Use flexible joints to prevent piping loads or other loads from being placed on the pump.

Refiner

- If you require higher precision performance, we recommend installing a refiner.

Pulse Counter

- Use of the pulse counter allows you to calculate the approximate discharge volume, for example, the number of shots output by the pump per minute.

- It is also handy for batch injection and for checking the pump’s running status.