Need help with this product? We’re ready and waiting for your questions/inquiries.

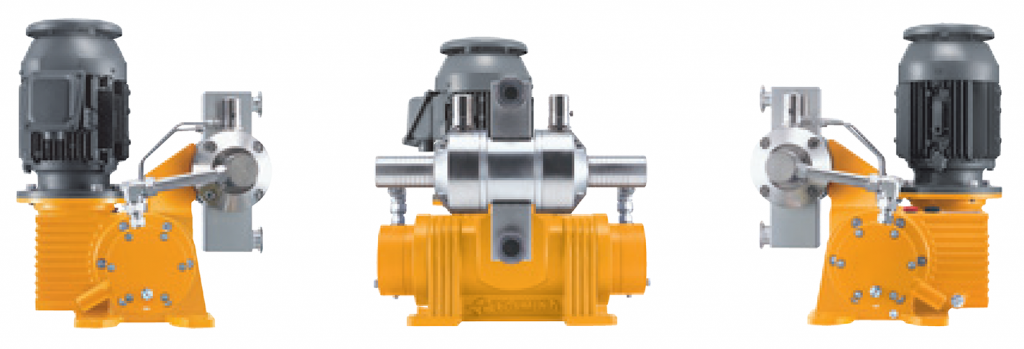

It has been common knowledge that satisfactory pulseless performance cannot be expected from diaphragm-type metering pumps which repeat the reciprocating in the high-tech field, where micron-unit precision is required. TACMINA has defied this common knowledge of the industry.

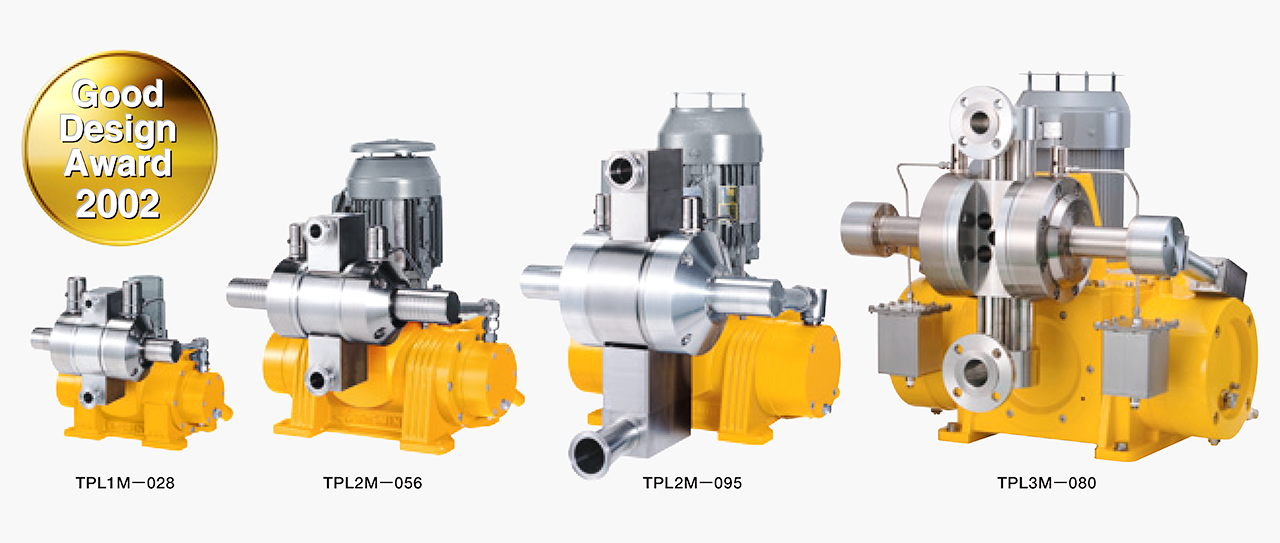

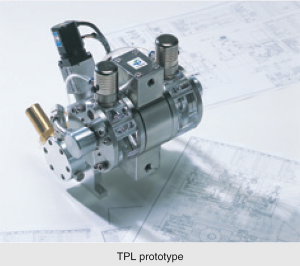

TACMINA concentrated the technical power cultivated over half a century, gave functional priority, and eliminated precision errors to the limit. As a result, TACMINA has developed a diaphragm-type metering pump with an innovative design, excellent maintainability, and pulseless performance defying the conventional concept of diaphragm-type metering pumps.

It may be more suitable to call the TPL Series a system rather than a pump due to the state-of-the-art specifications of the product.

TPL Series, the new current of liquid transfer, will increase the production efficiency of a variety of applications including those in the high-tech field, thus assuring you of great safety and reliability.

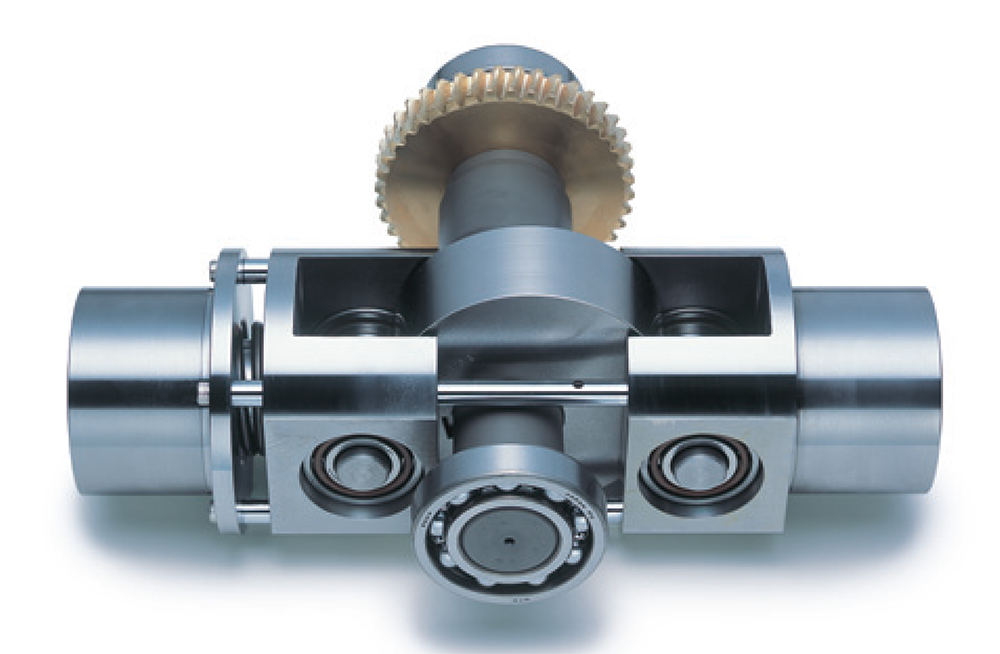

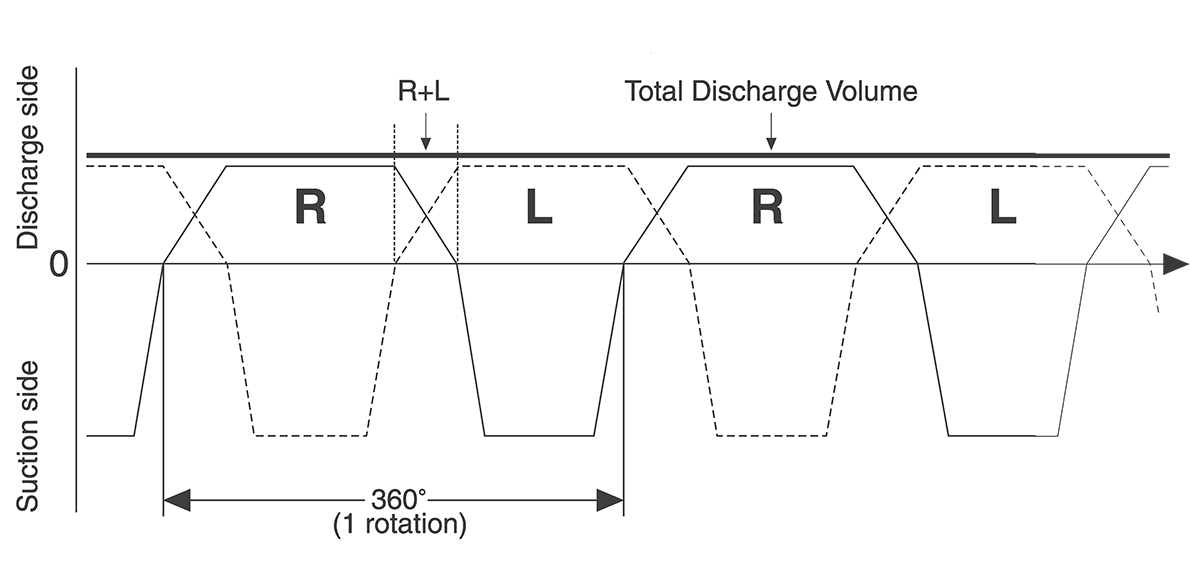

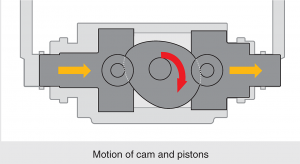

■An excellently constant flow is realized by the adoption of special-formed eccentric cam.

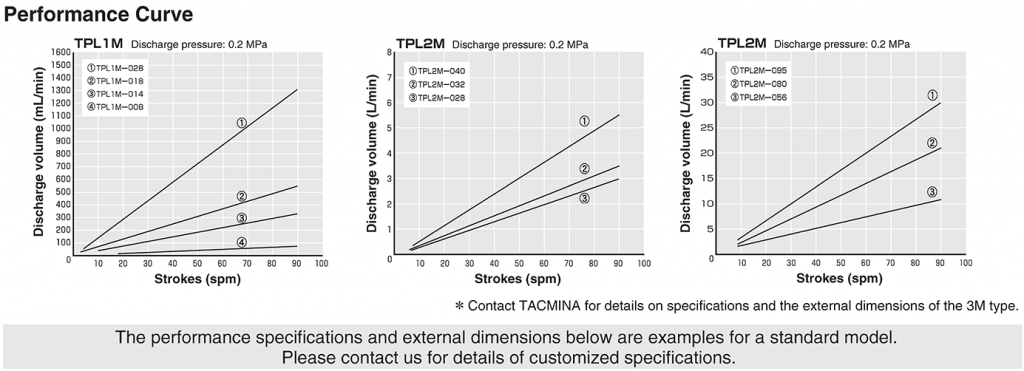

A conventional duplex metering pump converts the rotary motion of cam into reciprocating motion, thus causing pulsation. The TPL’s unique special-formed eccentric cam solved this problem. By keeping the total sum of discharge volume of both left and right pump heads, it has achieved unprecedented ultra-constant liquid flow.

■A perfect sealing with no liquid leakage.

The TPL has no movable sealing parts, thus ensuring no worry of liquid leakage or the exposure of transferred liquid to the air. The TPL is not only ideal for toxic or easy-to-evaporate liquid but also suitable to clothes, cosmetics, and food production processes, because there is no fear of the generation or contamination of foreign matters. Furthermore, the TPL supports HACCP (Hazard Analysis and Critical Control Point) applications.

■Precisely transfers extremely small amounts.

The TPL employs a special valve seat mechanism that maintains high precision at the time of liquid transfer no matter how small the amount is. This is ideal for applications, such as chemical mixing processes where accurate mixing ratios and transferred amounts are required.

■No damage to liquid and no fear of liquid degradation

Unlike other pumps, the TPL does not stir or locally compress liquid. This enables the transfer of food, chemical liquid, or slurry, the properties of which are not allowed to deteriorate as a result of shearing, abrasion, or pressure or temperature changes.

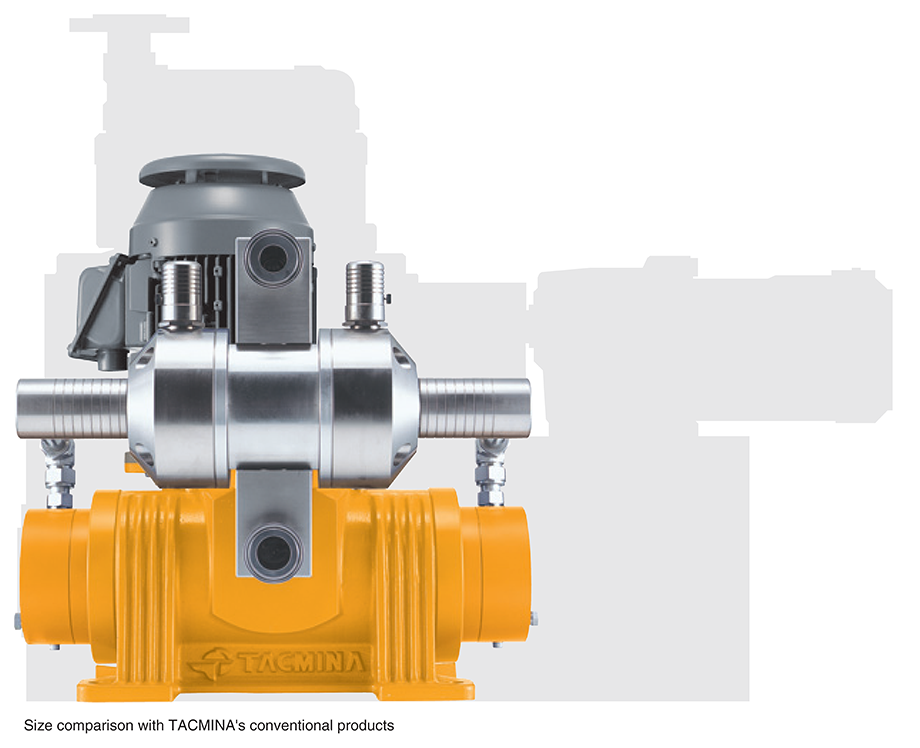

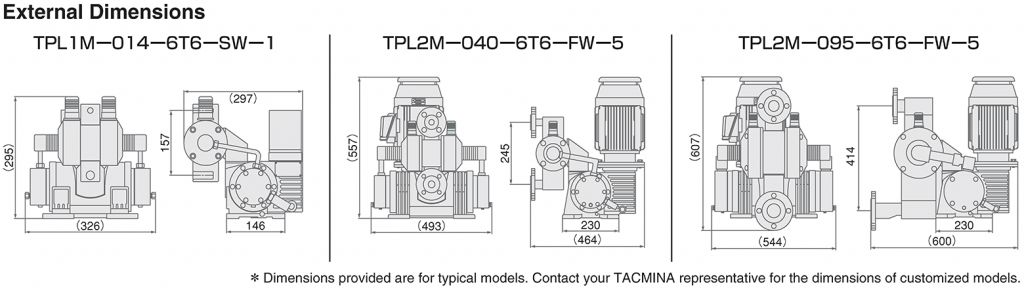

■A subminiature design with an approximately 1/2 of the conventional installation area of TACMINA's conventional models

A compact body was designed by making full-fledged use of a 3D CAD system with a thoroughgoing analysis of the material and rigidity of all the detailed parts of the pump. The required area of installation is almost half of that of TACMINA’s conventional models of the same capacity. This has solved a variety of problems in installation places, piping work, and maintenance.

■Efficient equipment greatly reduces loss of materials.

The interior capacity of the pump was downsized with the integration of the two pump heads. Furthermore, the TPL is pulseless, which makes it possible to downsize the diameter of the pipes, valves, and elbows on the discharge side. Therefore, loss of expensive process fluids can be minimized.

■Ideal production processes improve productivity.

Pulse elimination realizes the automatic, continuous operation of process lines. The TPL has solved conventional problems in production processes, such as efficiency (time contraction), improvement in yielding (production efficiency), and labor saving (labor efficiency). Furthermore, the TPL does not let the fluid come in contact with the open air, contamination with air bubbles, or irregular infusion, thus significantly improving product quality.

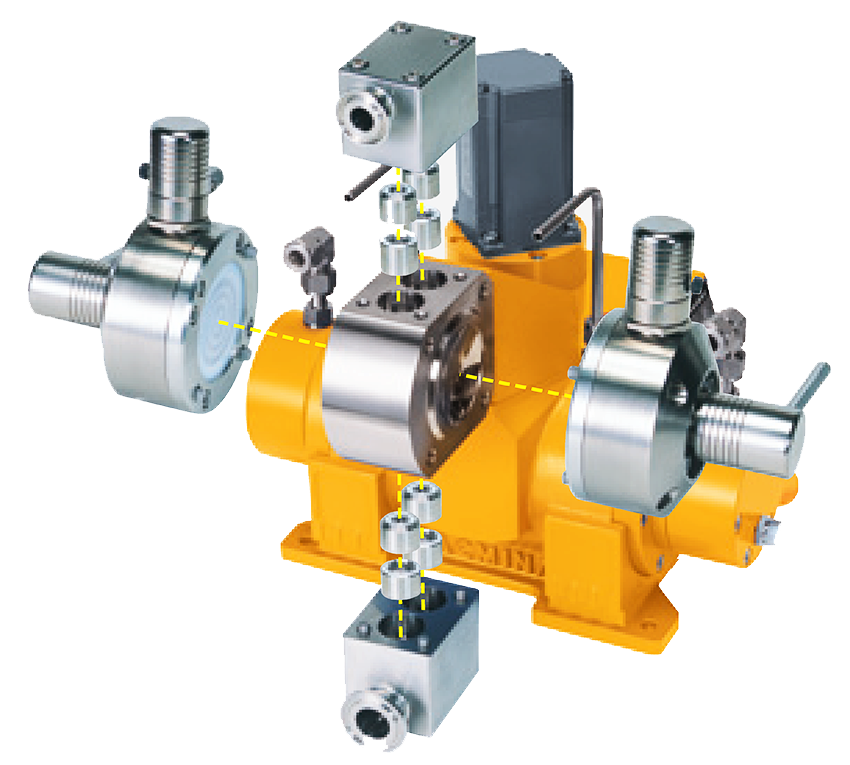

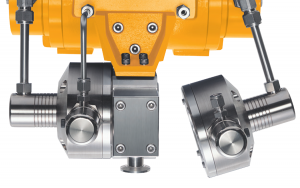

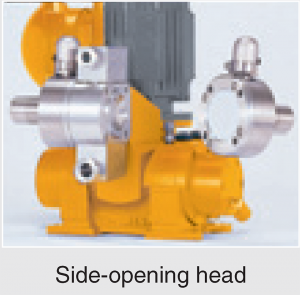

■Allows the replacement of parts and ease of maintenance without disconnecting the liquid pipes.

The modular design of the pump makes it possible to use only a hexagon wrench and a spanner to disassemble the pump into eight blocks with ease. The pump heads also use a unique side-opening system, allowing internal inspections, cleaning, and part replacement without removing the pipes.

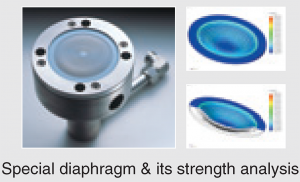

■Extension of the service life of the diaphragm reduces the frequency of maintenance.

The diaphragm newly designed with a close 3D analysis has excellent durability with a ductility of approximately four times as high as TACMINA’s conventional diaphragms. In addition, a special hydraulic mechanism is adopted to prevent the diaphragm from knocking the pump head component, which ensures a longer service life of the diaphragm.

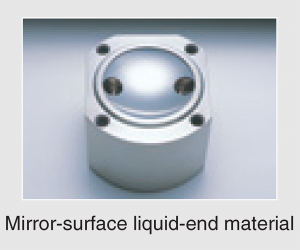

■Allows in-line cleaning to maintain the good quality of the system.

The inner surface of the pump head component coming in contact with liquid is mirror finished, which rejects liquid, thus sufficiently allowing in-line cleaning. Further- more, the special shape of the interior of the pump head component prevents the retention of the liquid in transfer and suppresses the occurrence of contamination, thus maintaining the quality of the system.

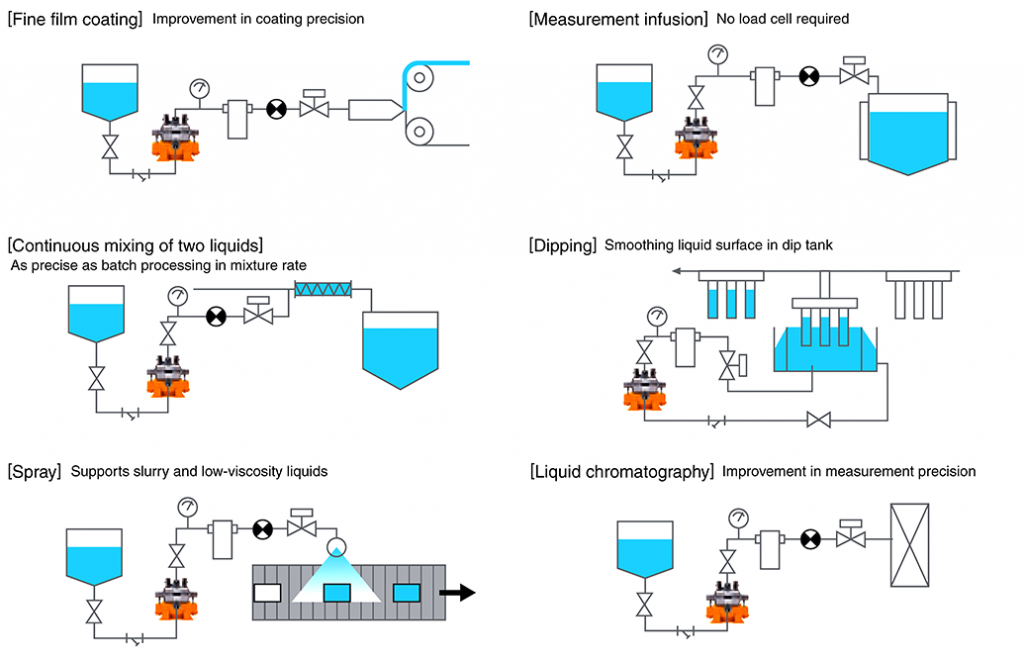

POTENTIALITY

Flexibly responds to applications with strict requirements, such as fine film coating and electronic component production stages.

An excellently constant flow responds to processes requiring strict quality control.

TACMINA’s TPL is a new current of liquid transfer for a variety of applications, such as fine film coating, measurement processes and in-line (continuous in-pipe) infusion in the leading-edge field, sample liquid supply for liquid chromatography.